Home »

How to Reduce Container Shipping Costs

Contents

Inflated Shipping Expense

Section 1 :Supply Chain Strategy

- Re-examine Overall Supply Chain Strategy

- Consider Alternate Transportation Modes

- Choose A Different Port

- Institute A Purchase Order Management System

Section 2:Planning

- Build Buyers Consolidation Loads

- Be Flexible On Ship-Time Requirements

- Benchmark Rates

- Adjust Shipment Timing

Section 3:Origin

- Negotiate An Incoterm

- Utilize An FTZ At Origin

- Maximize Container Payload

- Avoid Pallets By Floor Loading Containers

- Use Non-Operating Reefer (NOR) Containers

Section 4:Destination

- Transload Freight To Save Money

- Minimize Detention And Demurrage Fees

- Defer Duty Payments And MPF Charges

- Choose Warehouse Partners

Section 5:3PL Partnerships

From Volatile Seas To Smooth Sailing

20 Practical tips to save dollars and time

Don’t Let Inflated Shipping Expenses Shrink Your Profit

Transportation and logistics-related expenses typically absorb from 9%–14% of a company’s total revenue. With 90% of globally traded goods moving via ocean freight (Intl. Chamber of Shipping), container freight is an obvious focal point for cost reduction.

When talking about reducing container shipping costs, let’s be frank: it’s hard to cut costs on the water. You’ve got to think bigger picture.

That means looking beyond just rates and hard dollar savings to the costs that can be avoided through faster shipment cycle times, more efficient processes, and improved quality.

It also means examining all aspects of container shipping – from strategy and planning to origin and destination charges to smart use of 3PL partners to find savings.

We’ll look at all these areas as we review 20 practical tips for reducing container shipping costs.

Some of the ideas you can act on immediately.

Some will take more time and collaboration with colleagues.

All are designed to grab the attention of the person in the corner office as she sees your company’s global transportation expenses shrink and profits rise.

Download Guide

If you prefer to download this article as a PDF, just complete the form. Otherwise, keep reading.

Section 1:

Supply Chain Strategy

Strategic planning author Henry Mintzberg said “Strategy is not the consequence of planning, but its starting point.” Any discussion of cost control in container shipping must start with strategy.

Re-examine Overall Supply Chain Strategy

Any logistics cost-saving analysis must start with strategy. Your current supply chain and shipping routes might seem set in stone, but even small tweaks can lead to substantial savings in container shipping costs. Here’s a case in point:

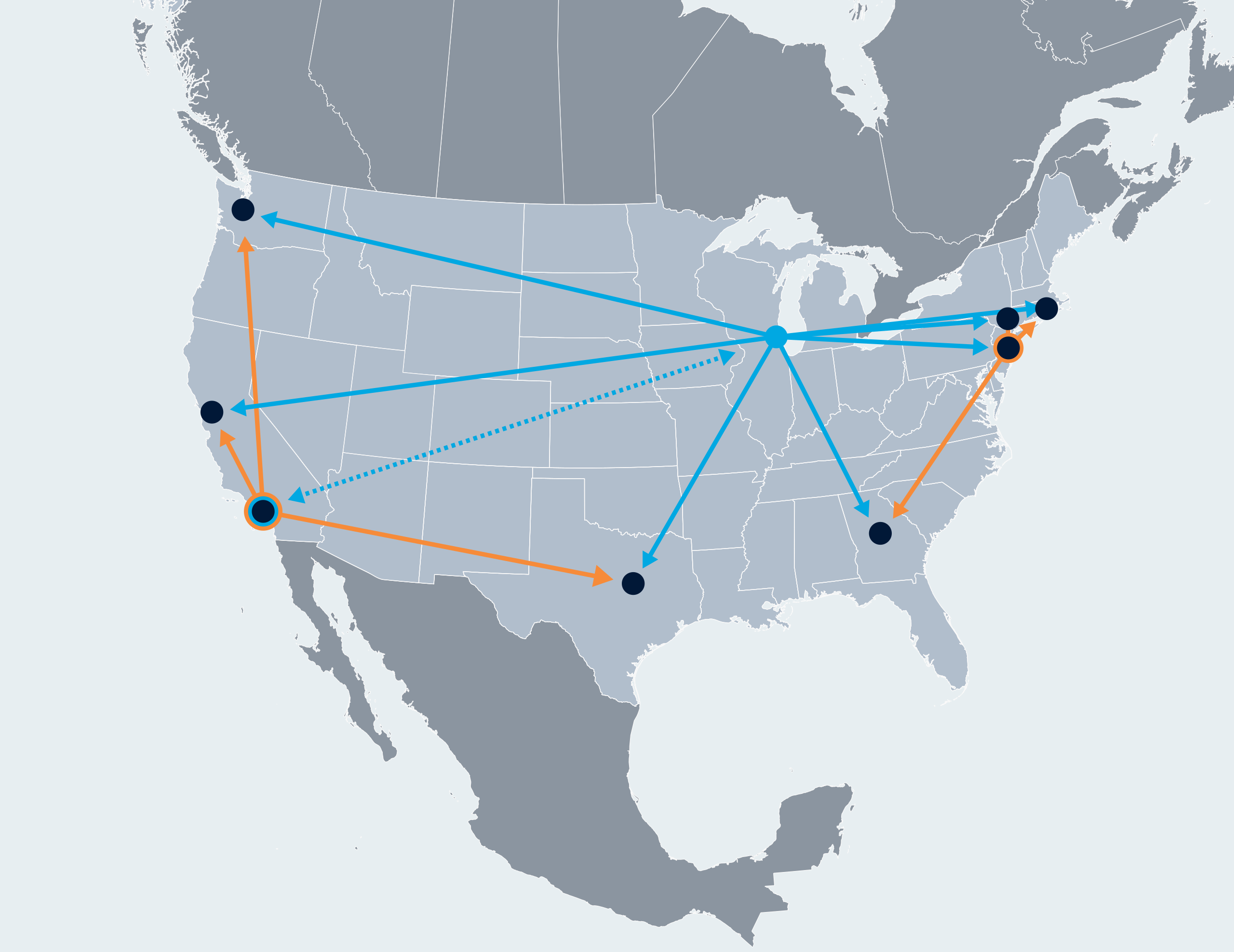

One industrial manufacturer struggles with inventory management, so the company ships containers from Asia into Los Angeles and then on to its Upper Midwest warehouse. Here, inventory is received, stored and eventually shipped on to key customers in New York, Rhode Island, Georgia, Dallas and, you guessed it, Los Angeles. Satellite locations on each coast would increase facility and inventory costs a bit but would eliminate millions of dollars in unnecessary domestic freight costs and cut the company’s cash cycle – from factory to final sale – by weeks. Container routing from Asia to the U.S. would have to be re-examined, but again the cost implications of this must be viewed in the context of the full supply chain.

A thorough evaluation of your distribution network takes time and considerable data analysis. But, while it may not be the lowest hanging fruit in a cost-reduction initiative, it has the potential to add millions to your bottom line once the network is fully optimized.

Consider Alternate Transportation Modes

Even though ocean shipping is the least expensive transportation mode, sometimes switching to another mode results in a healthier bottom line.

When container shipping costs increased on the Thailand-to-Batam (Indonesia) route, it was no longer cost effective for a Thailand-based tech company to accept the two-week ocean transit time. The company now works with Dimerco to move goods from the Thailand factory to Singapore via cross-border truck and then complete the journey with a short ocean voyage, cutting transit time by 7 days.

When transit time for ocean shipping increased sharply for its critical China-to-Europe lane, a China-based auto parts company could not meet strict deadlines from auto OEMs, threatening a loss of the business. The company switched from sea freight and now uses Dimerco’s China-to Europe rail solution (Xi’an to multiple ports in Europe) to cut transit time by 45 days and costs by 10%.

Don’t get locked into set transport modes and routing. Few sectors have changed recently as much as global container shipping. Those changes demand a fresh set of eyes and an evaluation of alternatives you may not have considered.

Choose a Different Port

Selecting the most cost-effective port for your imports and exports can have a noticeable impact on shipping costs. Evaluate different ports in your trade lanes and compare factors such as port fees, handling charges, and local transportation costs. Consider factors such as the availability of warehousing, customs clearance efficiency, and the overall infrastructure of the port. When you do that, you may decide that the fastest, most direct route is not the best for you. Here’s are examples:

A manufacturer of Uninterrupted Power Supplies needs the capacity of 45’ containers from Taiwan to Jacksonville, FL. Unfortunately, steamship lines will not accept 45’ containers into the Port of Jacksonville, so the importer was forced to use one 40’ high-cube container plus LCL or a 20’ container. The company decided to ship into the Port of Savannah, about 130 miles from Jacksonville, where 45’ containers are accepted. This solution eliminated the supplemental LCL or 20’ container – more than offsetting the higher drayage cost from Savannah.

For a manufacturing company, container shipments from Asia to Western New York State traditionally would go via the Port of New York and New Jersey – an all-water service with truck delivery to consignees. The service was fast, but costly. The company found it cheaper to use sea service into Vancouver and then intermodal rail to Toronto, with final-mile truck service from there. Transit times are slightly longer, but service levels were acceptable to the buyer and the company saves 10% on total freight costs.

As the saying goes, in a storm, any port will do. In global logistics, it’s important to choose the port that aligns best with your goals.

Institute a Purchase Order Management System

Across industries, there has been a worldwide shift away from paper-based processes to the use of automated workflows that enable real-time collaboration and decision-making in the cloud. Unfortunately, that shift has come slowly to the world of global transportation management, particularly at SMBs, where clerks rely on spreadsheets, emails and faxes to communicate with suppliers – and even other functions within the same company. Here’s an example:

A mid-sized global manufacturer surveyed its various supply chain functions to identify frustration points. What it learned:

Procurement professionals wanted better data to know what to order, when, and how much. But their order management system was separate from the logistics/shipping systems, so they lacked information on things like how much of a particular SKU is in inventory and when a just-ordered product would arrive at the warehouse.

The logistics team wanted better data on upstream purchasing activity to manage downstream logistics tasks. But they were not tied into procurement to know, for instance, what materials were ordered and the agreed date of receipt.

Sales and customer service wanted to tell the customer when new orders would be delivered. But to get this information, they had to ask the procurement or logistics team and wait for an answer.

The company eventually leveraged the Purchase Order Management system (POM) of its primary global transportation partner to facilitate collaboration between company departments, as well as overseas suppliers/ factories.

The right freight forwarder can be your ON switch for Purchase Order Management, letting you integrate all shipping processes with related POs to better manage the business and gain full supply chain visibility. It streamlines what is often a wildly inefficient and siloed process for container shipping. With a POMS, companies go from discrete management of shipments to having a centralized trail and archive of shipments by PO, with visibility from factory to final delivery.

Section 2:

Planning

Efficient shipping of container freight is not for the faint of heart. It requires close coordination with suppliers, forwarders, carriers, terminal operators, and customs agencies. Lots can go wrong, and those mistakes can cost you, big time. It pays to think before you ship. Here are some planning strategies to consider.

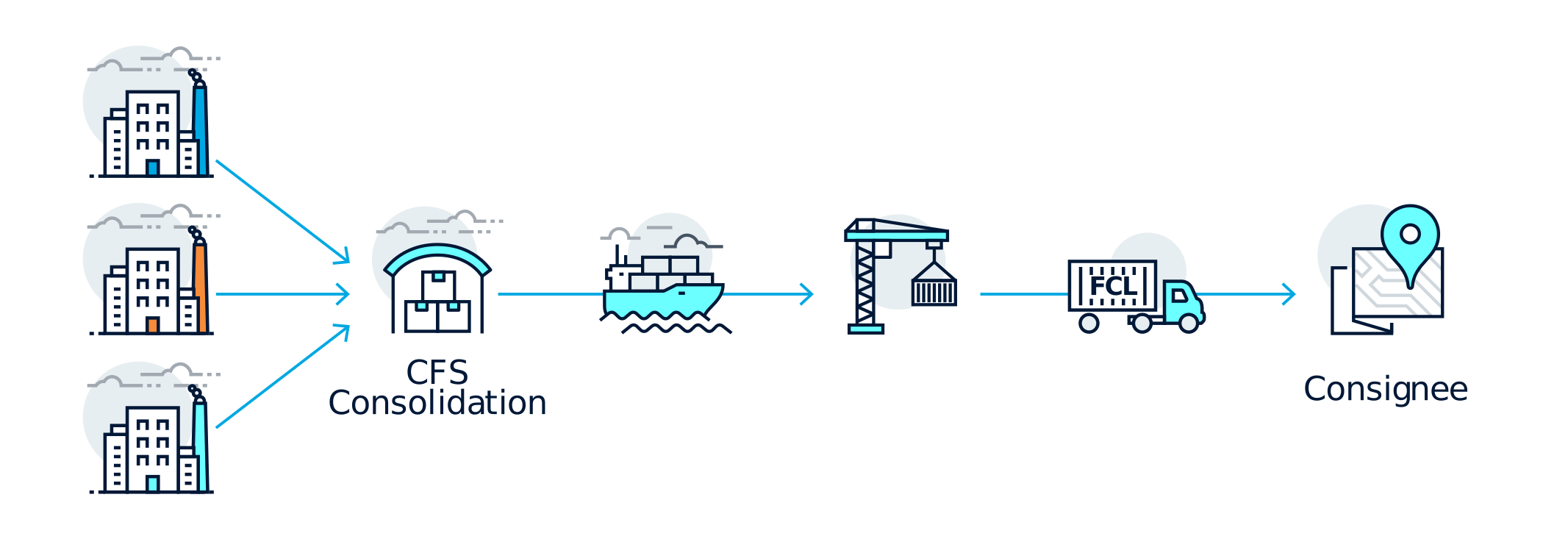

Build Buyers Consolidation Loads

It may cost less to book a full container, versus a partial container, when you have at least 20 CBM of cargo. But if you’re a smaller-volume shipper, you can work with your suppliers and the right freight forwarder to build your own full containers and pocket the savings. Here’s an example:

A U.S. manufacturer uses Dimerco to consolidate shipments from its different suppliers near Shenzhen, China and ship them door-to-door to different consignees in Toronto, Canada and Buffalo, NY. Cargo is consolidated at Dimerco’s Shenzhen warehouse and shipped out as LCL in a single container to Toronto, where cargo is divided for final delivery locally and to Buffalo. Ultimately, the customer gets a better rate due to the consolidation; Dimerco’s customer moves cargo faster than waiting for each consignee to order enough to fill one container; the consignees get their goods five days faster; and everyone in the chain pays less.

Where you have a dense concentration of suppliers, there could be an opportunity for a cost-saving buyer’s consolidation program for container freight.

Be Flexible On Ship-Time Requirements

Another way to reduce container shipping costs is to be flexible on your ship-time requirements. As you know from air travel, prices can vary greatly based on the day, week or season. The same is true of shipping lines.

Shipping when demand is lower results in cost savings as carriers offer more competitive rates to fill their vessels and better utilize capacity to avoid empty or partial sailings. Shippers with flexible sailing times will also benefit from shorter wait times at port and faster overall transit, reducing costs related to delays.

An importer of raw material for medical products recognized that there would soon be a steep cost increase for importing due to an upcoming rise in tariff rates and increased container rates. The company immediately shipped as much raw material as its warehouses could hold. That saved thousands of dollars by stocking up prior to the tariff increase and shifting transportation expenses forward to avoid shipments during a period of sky-high rates. These savings greatly exceeded the short term bump in inventory carrying cost.

Indirect routing is another strategy to consider. It will increase your overall transit time as vessels visit other ports en route to your destination port. But the strategy gives you more options to find a better rate, with a sailing that still adheres to customer delivery-time commitments.

Benchmark Rates

Container shipping costs change regularly, and sometimes wildly, up and down. As market rates shift, you want to make sure your freight forwarder’s rates are shifting similarly – particularly if the market softens.

Benchmarking prices is easy when buying fuel for your car. Just drive down Main Street and note the posted per-gallon/per-litre costs at several gas stations, then compare those prices to what you pay.

It’s not that easy to benchmark international container rates by lane. You’ll need to examine freight indexes, industry publications, shipping line websites, and talk to other freight forwarders. This effort takes time that can be hard to find in a busy schedule. But it may be worth it to prevent forwarders from booking added profit during bear markets.

Benchmarking rates is less necessary if you’ve forged a long-term, trusted relationship with a freight forwarding partner.

Adjust Shipment Timing To Avoid Peak Rates Or Known Rate Increases (GRIs)

In most industries, you don’t get advanced warning of a price increase. But in container shipping, you often do. If you stay close to the market and your freight forwarder, you can adjust shipment timing to save thousands of dollars.

In ocean shipping, carriers are legally required to file rate increases and alert clients at least 30 days in advance. But none are buying billboards or running prime time ads to get the word out. You need to pay attention.

While you can’t avoid General Rate Increases (GRIs) and Peak Season Surcharges (PSS), some short-term savings may be possible by shipping cargo early – prior to the effective date. This decision needs to be made early, as space right before the GRI/PSS implementation is often very tight.

Delaying shipments can also work since carriers often implement an increase and then reduce that increase in a couple of weeks if shipping volumes drop.

Our best advice: stay close to your freight forwarder. They know the market well and can advise you on how to minimize costs during periods of rate volatility.

Section 3:

Origin

Some of the most important decisions with ocean shipping happen where shipments originate. Races are often won by those who get the best start.

Negotiate An Incoterm That Maximizes Your Control Over Shipping Processes And Costs

Incoterms are the commercial selling terms between buyer and seller. There are 11 Incoterms that provide different options for dividing the responsibilities of buyers and sellers – basically, who arranges and pays for cargo delivery and who is liable for the cargo at different stages of the journey.

If you’re an importer, it can be cost-effective to take responsibility for managing your own international freight shipments. Many importers who allow the seller to route international air/ocean shipments (CFR, CIF, CPT, CIP, DAP, DPU and DDP terms) experience significant challenges when freight capacity is tight and supply chain disruptions are common.

Sellers sometimes refuse to move the goods, delaying shipments because of freight cost concerns or up-charging buyers for additional freight costs. Even small importers may find that routing their own cargo using EXW (Ex Works) or FOB (Free On Board) terms saves time, money and customer relationships.

A large lighting company contracts with a factory in Asia that insists on shipping cargo to the Port of Toronto. But in-transit visibility was poor. The company rarely knew when shipments were arriving and they often had unforeseen, and punishingly high, destination charges. Terms were DAP or CPT. The companies negotiated a change to EXW terms to give the importer full control of logistics, from beginning to end. As a result, shipping costs and transit times decreased and visibility was much improved.

Delegating responsibility in an international transaction can be tempting, particularly if you have a lean staff. But it may be better to control your own destiny. The right freight forwarder can help organize the details.

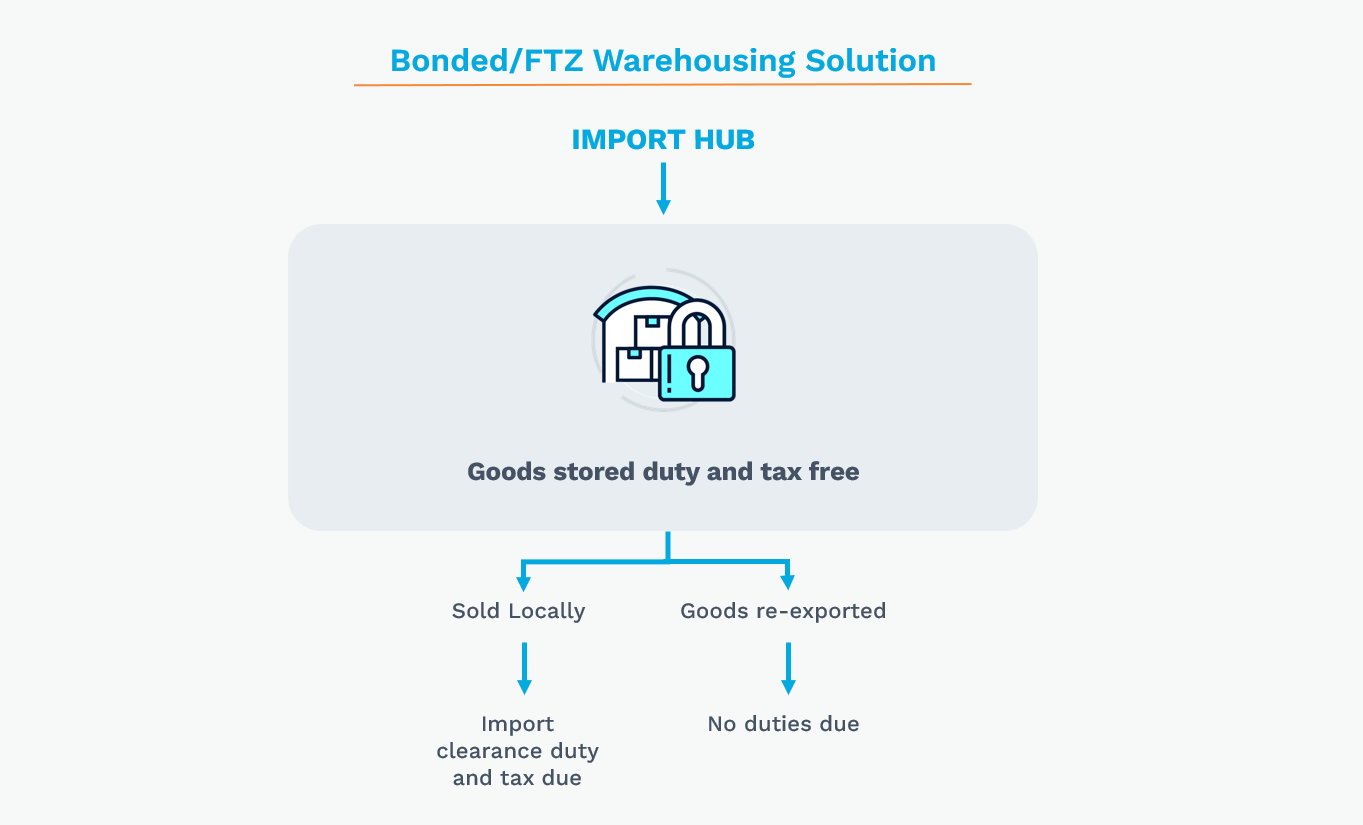

Utilize An FTZ At Origin To Save On Duties And Taxes

Strategic use of a bonded warehouse or free trade zone (FTZ) in Asia can help avoid or defer duty payments and speed tax rebates. One example is an

import warehouse.

Dimerco works with many suppliers that ship components into China to feed factories there. These suppliers store their inventory in one of

Dimerco’s many bonded warehouses pending customer orders. All duties and taxes on this inventory are deferred until the final sale, improving

cash flow.

If you are unsure of what tax advantages can be gained through use of bonded warehouses and FTZs, consult with a 3PL that operates such facilities to get a free assessment of the opportunity.

Maximize Container Payload

The math is pretty simple: the more cargo you fit in a container, the fewer containers you ship and the less you’ll pay in container shipping costs.

In 2019, Forbes reported that 65% of FCL containers bound for the U.S. were fully utilized. That’s a lot of air. If that utilization bumped to 90%, that’s 28% fewer containers shipped. If you ship 5,000 40’ containers a year from Shanghai to Long Beach, that’s USD $5 million–$10 million in savings – or even more depending on the prevailing container shipping rates.

To mine these potential savings, ask yourself:

Are my cartons too big for my items? If so, share the savings potential with your colleagues upstream and consider a packaging change.

Are pallets strategically loaded at the origin CFS, with the aid of a loading plan?

Would it make sense to load containers to the maximum weight and then arrange specialized heavy load transport at destination?

Sometimes the best ways to cut container costs are the simplest. Figure out how to get more cargo into your containers.

Avoid Pallets By Floor Loading Containers Or Using Slip Sheets

Another idea to improve container space utilization is to eliminate pallets, which can free up as much as 15% of the space. That translates into big reductions in container shipping costs, over time.

But floor loading also adds costs. While palletized cargo is unloaded efficiently with forklifts, floor-loaded cargo might take twice as long, as lumpers destuff containers manually.

You’d have to do the math on whether the shipping cost reductions outweigh the added labor costs.

The best items for floor loading are bulk, durable items that can be stacked. But if you’re talking about a container of children’s shoes with thousands of small boxes, the unload time of floor loading would be onerous.

Slip sheets are also an option that maximizes payload while avoiding a completely manual unload process. Slip sheets are thin sheets slightly wider and longer than pallets that are made from a variety of sturdy materials. While slip sheets require specialized equipment in the warehouse (a retractable push-pull forklift attachment) the benefits are compelling:

- Slip sheets can cost 10% of the price of a pallet

- Weight is 5% vs. a pallet and eliminates 4” of height, resulting in significant transportation cost savings

- Easily reused, recycled and discarded versus pallets, making slips sheets more environmentally friendly

- Less susceptible to contamination than pallets, which are good nesting spots for pests.

A Fortune 500 consumer goods manufacturer requires that Dimerco warehouses have slip sheet capabilities to manage container-to-truck transloading in Los Angeles. The added container space created from slip sheet use reduces the number of required container shipments on this lane. Unlike floor loading, by using the right equipment slip sheets maintain the same ability of palletized cargo to move multiple cartons at the same time.

Pallets, like containers, are a staple of ocean shipping. But they aren’t always the answer.

Use Non-Operating Reefer (NOR) Containers To Ship Dry Freight

For trade between Asia and North America, westbound cargo to China utilizes more temperature-controlled containers then eastbound moves to North America, which involve more finished goods. This creates an oversupply of reefers in Asia, particularly China. Carriers want to correct this imbalance by offering lower rates to shippers of dry goods who use a reefer container without its cooling function activated. These are called non operating reefers, or NORs.

Shifting from a standard 40-foot container to an NOR might save you 10%–30%, and even more during peak season.

NOTE: Carriers want cleaner cargo for NORs, so the strategy doesn’t work for all products. Also, if you want to stack goods to the top of the container, the stack height of a 40-foot, high-cube reefer is about a foot less than a standard 40-foot, high-cube container.

Section 4:

Destination

Extra costs can add up quickly after containers hit the port, with inland transportation, CFS costs, and demurrage and detention penalties. Controlling these surprise costs is essential.

Transload Freight To Save Money And Speed Delivery Cycle Time

If you’re shipping containers from Asia, there’s money and time to be saved by transloading your cargo from containers to trailers for fast truck delivery to customers. It helps when you use a forwarding partner that operates its own CFS. At Dimerco’s San Francisco CFS, for instance, we can turn around a container in as little as one hour and get freight on its way.

A design company ships regularly from China to LAX, then transloads containers and moves freight via truck to multiple states across the Midwest, South and East Coast. This strategy not only saves money versus shipping full containers inland, it also shortens transit time.

The advantages of container-to-truck transloading include:

- Reduce costs. The content of three 40-foot containers will fit into just two 53-foot dry vans. Overall ocean freight + transloading costs are less than regular FCL to inland cities.

- Avoid demurrage, detention and storage fees since containers are quickly returned to port.

- Cut delivery time as much as seven days versus rail, since trucks leave immediately after loading and travel direct to the consignee.

- Keep a percentage of the cargo near the port to fulfill regional orders and avoid shipping to an inland warehouse, only to have some of that same inventory return for final distribution.

Another perk: transloading makes your freight more desirable to carriers since they prefer quick container turns at the port of entry.

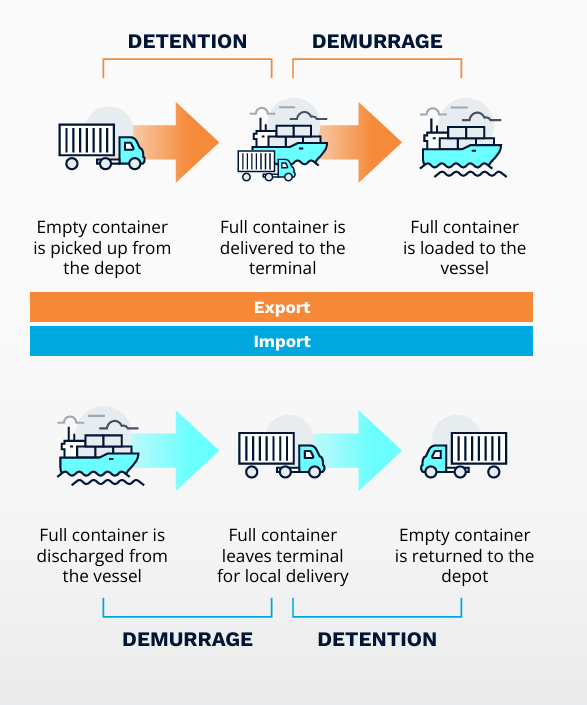

Minimize Detention And Demurrage Fees

Free time refers to the time ocean carriers allow customers to use port facilities and containers. If you don’t pick up your container in the allotted time, you pay a demurrage charge. If you return the container late, you get charged a detention penalty.

These fees vary by carrier and terminal, but they typically range from USD $75–$300 per container, per day.

A consumer product brand shipped 12 containers and was forced to delay pick up by seven days due to customs clearance issues. With demurrage at $150 per day, they were hit with a $12,600 charge.

Over the course of a year, those kinds of extra charges can blow up your freight budget. Here are some tips to control these costs:

- Know your free time limits. Surprisingly, many do not.

- Plan better and make sure all necessary documentation and pickup arrangements are buttoned up well in advance.

- Expedite customs clearance by having all paperwork accurate and ready.

- If you anticipate delays in picking up cargo, use nearby storage facilities to avoid accruing demurrage.

Of course, partnering with a reputable freight forwarder might be your best strategy. The right partner has experience in efficiently managing all details of port services and customs clearance.

Use An FTZ At Destination To Defer Duty Payments And MPF Charges

Most countries have their version of a free trade zone program to promote trade. These zones are government approved areas considered outside the country’s territory, so goods can be stored there “duty free” until they are sold or exported.

Most countries have their version of a free trade zone program to promote trade. These zones are government approved areas considered outside the country’s territory, so goods can be stored there “duty free” until they are sold or exported.

An FTZ is most beneficial to importers with high-value products and high duty rates. At such companies, the cash flow benefits of duty deferral outweigh the costs to operate in the zone.

One global manufacturer of cameras and accessories brings in 50-60 containers monthly from Asia to the Port of Long Beach and stores that inventory at a 3PL-operated FTZ in the Inland Empire Region 60 miles east of the port. This allows the company to defer around USD $6 million in taxes and duty payments for several months until the products ship out – a huge cash flow advantage.

In the U.S., another advantage of using an FTZ at destination, particularly for high-volume importers, is the ability to reduce Merchandise Processing Fees (MPFs) – a user fee assessed by U.S. Customs and Border Protection (CBP). MPFs are charged at .3464% of the value of the goods, per entry, to a current (2024) max of $614.35. FTZs allow you to file a single entry per week and pay the maximum fee only once, regardless of the number of containers.

A tech manufacturer imports an average of 10 containers per week into the U.S. If they stored their products outside an FTZ, MPF charges would be USD $6,143 per week and $319,462 per year. But because they are in an FTZ and file a single entry for multiple containers, they pay only $614 per week and $31,946 per year – an annual savings of $287,515

With FTZs, governments create opportunities to make trade easier and more economical. It’s wise to take advantage where it makes sense.

Choose Warehouse Partners With Flexible Hours To Avoid Carrier Fees And Yard Storage

When selecting a 3PL warehouse partner to receive and store your goods, prioritize 3PLs with extended or flexible operating hours. Some, not many, operate 24/7, while others may only unload containers from 6:00 am to 11:00 am.

When hours are less flexible, it adds to your door-to-door container shipping costs. For instance, an early morning container delivery requirement forces your drayage partner to pick up a day early and incur additional yard storage, and even chassis rental costs.

Flexible receiving hours avoid these costs and allow you to receive your imported goods outside peak hours, potentially reducing wait times.

Section 5:

3PL Partnerships

While you may manage global transportation strategy, it’s your chosen partners who will execute. Logistics is an execution business, so choose your partners wisely to reduce your door-to-door costs.

Choose The Right Ocean Carrier

Cost and service will vary among ocean carriers. Your freight forwarder can help you select the one that aligns best with your goals. But you’ll need to decide whether the lowest rate or the highest service level is your priority.

You might be able to save USD $200 per container but, as we’ve discussed, there is a cost to substandard service. Unexpected delays can trigger extra storage and freight costs and erode customer confidence.

Your freight forwarder knows the relative strengths and weaknesses of carriers and can help you choose the best fit by lane.

Take Advantage Of The Buying Leverage Of NVOCCs

When you book ocean freight, you can contract directly with the carrier or contract with a non-vessel operating common carrier (NVOCC). The largest container shippers will work directly with carriers, but the vast majority of companies have little leverage with those carriers and are better off with an NVOCC.

NVOCCs are the wholesale buyers of the ocean shipping sector. They negotiate carrier rates based on their aggregate freight spend across all customers. By booking through an NVOCC, you get significantly reduced rates and gain access to multiple ocean carriers’ capacity – without the need for you to enter into a contractual commitment and/or build long-term relationships with each carrier.

Some NVOCCs are also full-fledged freight forwarders. Think of forwarders as the freight shipping concierges of the industry. They manage all aspects of door-to-door global transportation on your behalf.

This shipment coordination aspect of an NVOCC’s service could be even more valuable than lower rates. Freight coordination comes as part of their service, so you avoid hiring staff to work with carriers, complete and file paperwork, monitor shipment progress, and manage the myriad other details involved in global shipping.

Integrate With ONE 3PL For Door-To-Door Service To Simplify Global Freight Management

Managing international shipments involves juggling multiple service providers – truckers at origin, ocean carriers, customs brokers, truckers at destination, warehousing partners, insurance providers and others. To avoid the time and cost of having your small team manage these details, think about simplifying your logistics operations by using a 3PL that offers global shipping, warehousing, and first- and final-mile delivery as part of a single-source, door-to door shipping solution.

This works best when the 3PL has offices at both origin and destination, avoiding the use of agents that add a layer of communication and coordination. Here’s an example:

A Canada-based manufacturer of premium building materials uses Dimerco to manage a buyer’s consolidation program in China, with freight moving from Shanghai to Vancouver. Dimerco’s Vancouver office works with the Dimerco office in Shanghai to coordinate with 3-5 different suppliers who ship into Dimerco’s Shanghai warehouse for consolidation. Once containers ship from Shanghai, all paperwork is automatically shared over Dimerco’s global operating system with the Vancouver team, who coordinates customs clearance, port services, and final delivery. The consolidation itself saves this customer 10-15% on freight versus standard LCL shipping. And, by simplifying the shipping process with one provider, the company saves hundreds of hours in coordination time.

Integrating all aspects of your supply chain with one 3PL provider allows for greater visibility and control, streamlines communication, reduces coordination efforts, and eliminates the hassle of dealing with multiple vendors.

From Volatile Seas To Smooth Sailing

The most important and visible evidence of a well-run logistics operation is how much it costs to deliver the service levels the business demands. Those who can get the job done – and do it for less – earn corner office attention. This eBook deals with this irrefutable reality.

In the past several years, few industries have experienced the roller-coaster ride in pricing that global shippers have had to endure. Through it all, the pressure on logistics cost control has not eased. If anything, global shipping costs are under even greater C-level scrutiny – and that pressure flows down to you.

The good news is there are many different levers you can pull to control door-to-door container shipping costs, even in the throes of significant rate volatility. The tips in this eBook are a good start. With the right approach, you can save money, streamline your global shipping operations and, ultimately, inspire the confidence of customers and shareholders.