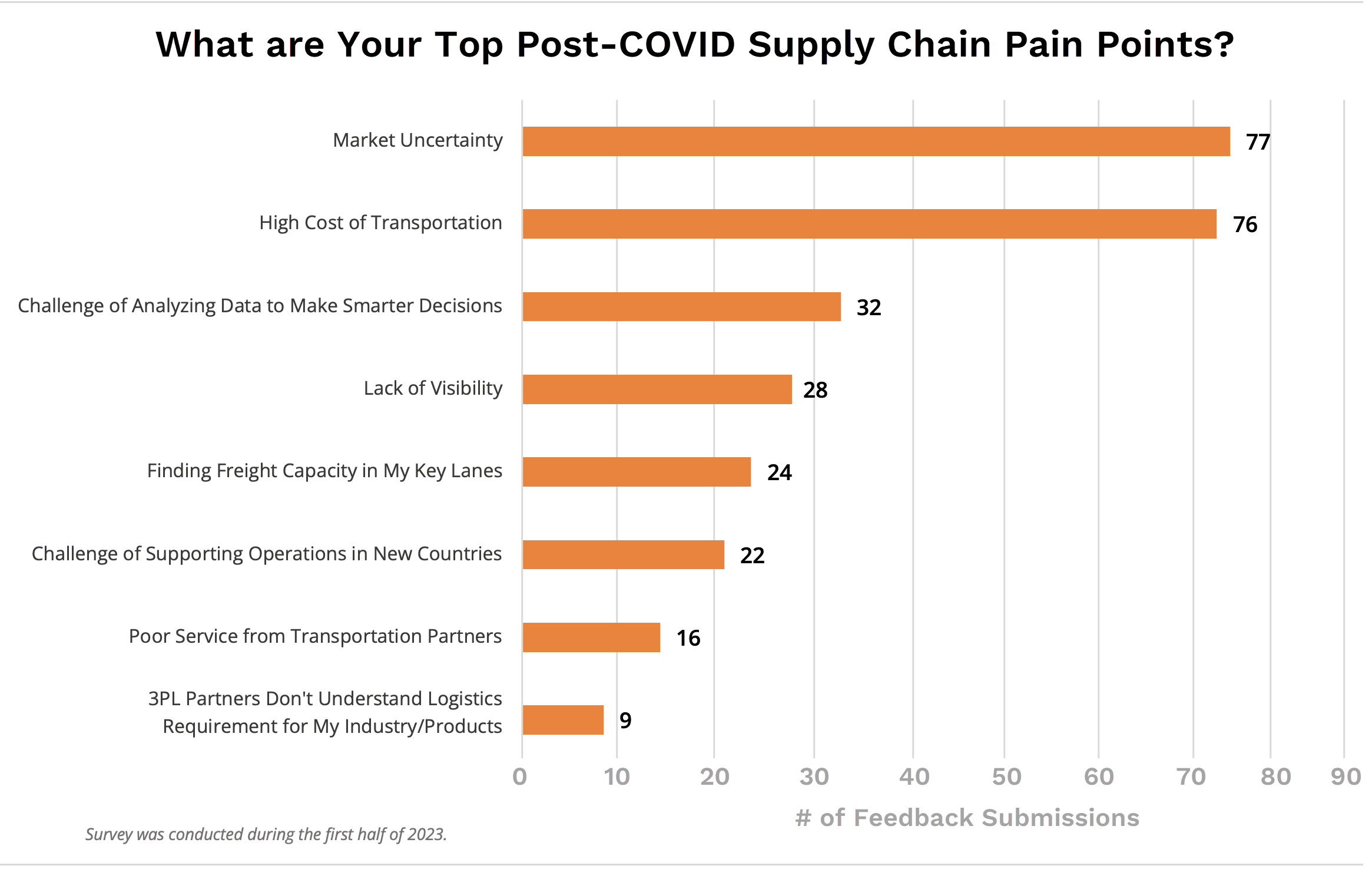

During the first half of 2023, we asked supply chain executives to name their top post-Covid supply chain pain points. Two emerged as the dominant choices: market uncertainty and high transport costs. All other responses were far down the list.

The concern over high transportation costs comes at a time when demand is down and rates are falling. But this survey result is not totally surprising. When consumer demand is soft there is pressure on corporate bottom lines, and that puts a spotlight on controlling logistics costs.

The top pain point – market uncertainty – is the real headline of these survey results and provides a strong clue about the characteristics of tomorrow’s logistics operations.

Uncertainty is painful, why?

Because when markets change, so must logistics operations and freight networks. That’s easier for some than others. Some comments from our survey participants:

- “Balancing inventory post-Covid has been hard. With market uncertainty, we have been left second guessing more.”

- “In this volatile market, we cannot execute long-term plans.”

Large global companies are at a disadvantage in unpredictable markets that require quick reaction to changes. That’s because change happens slower at such organizations.

If market uncertainty is the new normal, then these large enterprises need to figure out how to become more nimble. One way to do that is to align with a 3PL that can move and flex quickly, providing the agile logistics infrastructure required to compete.

But be careful here. Some of the largest 3PLs are as slow moving and bureaucratic as their big customers. In this market, don’t underestimate the advantages of speed and agility.

When HP needed to integrate data feeds among 30 different suppliers and carriers, Dimerco Express Group (one of HPs global transportation partners in Asia) handled this complex EDI project within 30 days. That prompted HP’s procurement manager to comment that “similar integrations have taken us 2 to 3 months.”

To compete in the future, large enterprises must transform their supply chains and distribution operations to adapt quickly to changing market conditions and customer requirements. Agile 3PLs can help.

Traditional Supply Chain Planning is Obsolete

Uncertainty is also painful because it makes traditional supply chain planning obsolete – plans with suppliers, with carriers, and with 3PLs.

When you study the success stories of pioneers like Thomas Edison, Bill Gates, and Elon Musk, all talk about the importance of failing fast. Of scrapping existing plans, recalibrating on the fly and adapting quickly to what the market wants. That need is certainly evident among our survey respondents:

- “Presently we are reorganizing and relocating to several new markets. That’s got to be done quickly and done well.”

- “During the pandemic, many companies collapsed because they couldn’t adapt.”

When change is the only certainty, logistics operations must be able to support this “change fast” ethos. Dimerco’s eBook on The Logistics of China Plus One includes several examples, including this one:

In the face of punishing tariffs and falling market share, a maker of steel equipment for the solar panel industry relocated from China to Malaysia to avoid China-origin tariffs. Dimerco advised the company on local duties, compliance regulations and free trade zone usage in Malaysia and transitioned the operation seamlessly with minimal disruptions.

Supply Chain Pain Points

Supply chain curriculums inside and outside universities can teach us how to evaluate and plan logistics to achieve the right balance of service levels and inventory – in a predictable world.

But they don’t teach us how to build a supply chain and distribution infrastructure that can flourish in an unpredictable world.

If market uncertainty is your biggest post-Covid supply chain pain point, you may need a global logistics partner like Dimerco that can turn change into your competitive advantage.

Need to connect your Asia-made products and components with the rest of the world? Let’s talk.