No symbol is more representative of global trade than the ocean shipping container. An estimated 849 million containers are shipped globally (Statista, 2023), accounting for about 80% of the goods being shipped. But containers come in different shapes and sizes. It’s wise to be familiar with the different options so you can choose the one that makes the most operational and financial sense for your company.

Following is a Q&A-style primer on ocean freight container specifications and what you need to know.

What are the common types of shipping containers?

Apart from the 20ft standard and 40-foot standard containers, there are other types to consider.

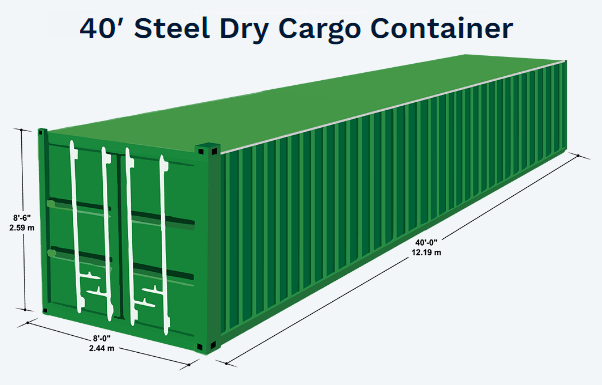

Dry cargo: The standard shipping boxes commonly seen at sea, perfect for transporting general cargo such as furniture, electronics and clothing.

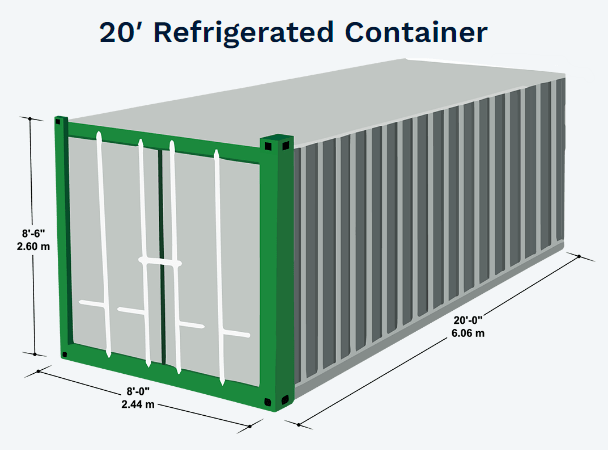

Reefer: These containers come equipped with refrigeration units, making them ideal for transporting temperature sensitive goods.

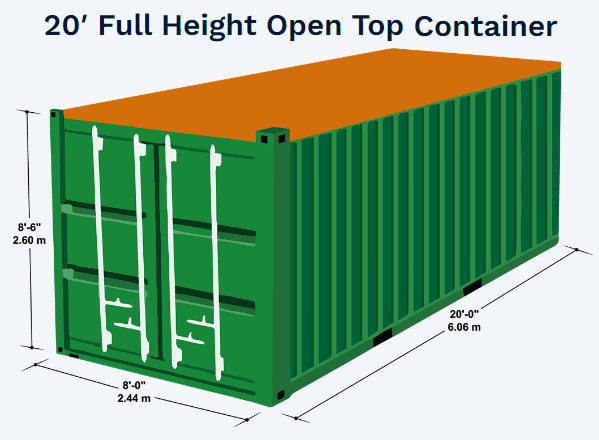

Open Top: Featuring removable roofs, these containers transport oversized or tall cargo like machinery.

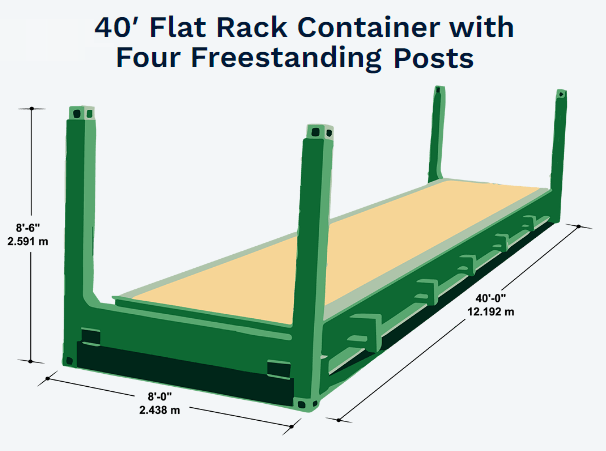

Flat Rack: With collapsible sides that transform into platforms, these are versatile for transporting irregularly shaped or large cargo.

High-cube: The taller version of dry cargo containers, offering extra space for voluminous but lighter cargo.

Is there a guide that provides the dimensions of all the different types of ocean container sizes?

Explore Dimerco’s extensive guide on ocean freight container specifications, diverse range of container types and sizes available. Whether you’re shipping standard cargo, oversized items, or specialized goods, our guide provides the information you need to make informed designs. Find the perfect container tailored to your cargo’s type, column, and shape.

How much weight can I load into a container?

The max container weight limit is the “maximum gross cargo weight” listed on the container door. That’s typically around 55,000 lbs for a 40-ft container. But most shippers try to stay within legal road weight restrictions. For instance, in the US restrictions on roads limit total weight to 80,000 pounds for a standard tractor-trailer. When you factor in the weight of the truck, chassis and container, that leaves about 42,000–44,000 lbs for the actual ocean container capacity. If you go over that, you’ll need to use trucking partners with special equipment and special permits to transport heavy loads.

If you ship dense cargo – like knock-down furniture or stone or metal products – it could make good financial sense to maximize the container weight and then pay extra for specialized land side transportation. If you can add 10,000 more pounds to every container you ship, you’ll ship 25% fewer containers, so the ocean savings could more than make up for the added road transport costs. It will depend on the commodity. Most shippers try to keep container cargo weight below 37,000LBS for 20’ and 42,000LBS for 40’to meet road transport weight limits.

Should I ship in a 40-ft or 20-ft container?

A 20-foot container has half the ocean container capacity of a 40-foot unit; but it costs about 80-90% as much. 20-ft containers are suitable for heavy cargo because such cargo may hit a max weight limit in a 40-ft container long before the container is even close to full. You can still save a little by shipping in a smaller box, so you’ll need to evaluate your specific needs. Let’s take an example. If you have a shipment of auto parts that weighs 74,000 lbs, you may be able to fit the entire shipment with 40ft container dimensions, but weight restrictions prevent you from doing so. In this case shipping two 20-ft containers – each loaded with 37,000 lbs of cargo – would be your cheapest option.

A 20-foot container has half the ocean container capacity of a 40-foot unit; but it costs about 80-90% as much. 20-ft containers are suitable for heavy cargo because such cargo may hit a max weight limit in a 40-ft container long before the container is even close to full. You can still save a little by shipping in a smaller box, so you’ll need to evaluate your specific needs. Let’s take an example. If you have a shipment of auto parts that weighs 74,000 lbs, you may be able to fit the entire shipment with 40ft container dimensions, but weight restrictions prevent you from doing so. In this case shipping two 20-ft containers – each loaded with 37,000 lbs of cargo – would be your cheapest option.

Should I ship FCL or LCL?

Deciding between a full-container load (FCL) or less-than-container load (LCL) for your ocean shipment involves understanding your specific needs and priorities. Here’s a breakdown to help you choose the right option.

When you ship an FCL, it means you have enough cargo to fill or nearly fill a container. Here are the pros:

- Faster transit times due to direct port-to-port delivery.

- Lower risk of damage from fewer handling points.

- No customs delays caused by other shipments in the container.

- Greater control over packing and security.

Here are the cons:

- Higher overall cost, even if you don’t fill the entire container.

- Less suitable for smaller shipments.

When you ship a LCL, it means your shipment is small and you may be able to reduce your shipping costs by using a freight forwarder to consolidate your cargo with other shippers. Here’s why it’s advantageous:

- Lower cost per unit shipped due to shared container costs.

- Flexibility ideal for smaller businesses or occasional shipments.

While LCL shipping has advantages for small-volume shippers, here are some downsides you should be aware of:

- Longer ship times. FCL loads can move direct to the port at origin and direct to the consignee at destination. LCL loads must go through a container freight station at each side for consolidation/deconsolidation. How much time can this add to the trip? As an example, from LA to Shanghai LCL service adds around 9 days versus FCL.

- Increased chance for damage. More touches means more opportunity for damage. Also, you are sharing the container with other products, so shifting cargo in transit could cause problems.

- Customs delays. With an LCL shipment, if just one of the partial shipments on the container experiences issues, it delays the whole shipment.

LCL will cost you less per unit of freight shipped, you save by sharing the shipping costs with other small-volume shippers. There is a breakeven point at which a large LCL load equals the price of a dedicated 20-ft container. An experienced global freight forwarder like Dimerco can advise what that point is based on your commodity, shipping lane, and other current market rates.

What are the key considerations for FCL vs LCL?

Shipment size: How much cargo are you shipping?

Budget: Can you afford the higher upfront costs of FCL?

Urgency: How quickly does your cargo need to arrive?

Risk tolerance: Are you comfortable with potential LCL downside?

Who loads the container?

It’s almost always the shipper that loads the freight for FCL loads. Loading of LCL containers is done by the freight forwarder arranging the consolidation. Proper loading requires exact knowledge of ocean freight container specifications.

How much does a sea shipping container cost?

Understanding the exact cost of your ocean shipment requires considering several factors like container size (FCL or LCL), origin and destination ports, current market rates, and specific needs. For a personalized quote based on your specific needs, please contact us today.

What if my freight doesn’t fit in a standard ocean container?

Freight that is over height or over width is called out of gauge cargo, or OOG. For cargo that fits within the width and length dimensions of a container but is too high, Open Top containers are the most economical choice. These are loaded from the top by a crane and dropped into the container.

Over-width cargo can use a Flat Rack container, which has the sides and top open. The floor of a Flat Rack is a foot thicker than the floor of a standard container. You want to make sure that the load is tightly secured to avoid damage. And you’ll need protection against the elements with a tarp or shrink wrap, depending on the product.

Both Open Top and Flat Rack containers come in 20-ft and 40-ft options. These specialized containers will cost a little more. If your shipment is deemed OOG cargo, it will require special permits when it travels on the road, making it more expensive to ship. Railroads won’t accept OOG cargo at all.

How about shipments requiring temperature control?

20-ft and 40-ft refrigerated containers (reefers) have built-in air conditioning units that need to be continuously powered up and programmed to meet the product’s temperature and humidity requirements. Trucks that haul these containers to and from terminals need to have a generator set, or genset, unit. Terminals can provide plugs to keep reefers powered during loading and unloading. And the cargo ships themselves have plugs for reefers.

All steamship lines offer 40-ft reefers, but only some offer 20-foot reefers.

All steamship lines offer 40-ft reefers, but only some offer 20-foot reefers.

Reefer containers look different than standard containers on the inside. Walls will be aluminum, not steel. The floor, instead of wood, is a series of aluminum rails that allow air to circulate under the cargo. Reefers are mostly used for food products, but composite materials like carbon fiber may ship in reefers, as well.

BONUS TIP:

Think about insuring your temp-controlled cargo. The A/C units usually work, but not 100% of the time. You don’t want to risk losing $40,000 worth of meat to avoid $175 on marine cargo insurance.

Rely on Ocean Freight Shipping Experts

As you can see, there are many types and sizes of containers with different ocean freight container specifications. You want to make the right choice based on what you are shipping and the volume. CBM calculators can be a useful tool to calculate a consignment’s weight and volume. Or, you could leave the details to ocean freight shipping experts like Dimerco, who can provide guidance on global trade compliance and ensure your shipments are handled efficiently and in accordance with international regulations.

To discuss how Dimerco can help manage your ocean shipments, contact one of our international shipping experts to start a discussion. We ship globally, but our particular strength is the Trans-Pacific lane where we enjoy preferred partner status with all top Asia-based ocean carriers.