When it comes to product distribution – across Asia or anywhere in the world – companies want to do it faster at the lowest possible cost. One of the barriers to achieving these dual objectives is the lack of warehouse process automation found within most distribution warehouses. With all the talk of digital transformation in the logistics industry, many companies, large and small, continue to rely on manual data entry and spreadsheets to get the job done.

Businesses cannot compete successfully if they continue to utilize old-school tools and tactics for warehouse distribution. To drive down costs and distribution cycle time, these companies must align with third-party logistics providers (3PLs) that can apply digital logistics processes to reduce distribution time and costs.

What’s wrong?

Many companies prefer to invest available capital to develop their core businesses, rather than automating their distribution infrastructures. As a result, they rely on 3PL support in the global markets where they operate. These 3PLs offer wildly varying levels of service and many are still at the very early stages of digital transformation. As a result, their customers suffer from slower, more costly distribution operations.

Many companies prefer to invest available capital to develop their core businesses, rather than automating their distribution infrastructures. As a result, they rely on 3PL support in the global markets where they operate. These 3PLs offer wildly varying levels of service and many are still at the very early stages of digital transformation. As a result, their customers suffer from slower, more costly distribution operations.

Key symptoms of inefficient product distribution include:

- Inventory data is decentralized at each warehouse location. As a result, there is no single view of inventory in the system to support decisions on when to place new orders. Without synchronized data on system-wide inventory levels, by SKU, inventory levels are likely too high or too low.

- Warehouse processes are highly manual, with a lot of data entry. As inventory enters the distribution warehouse, key data comes with it, like bills of lading and packing lists. Too often, clerks are entering this data into the 3PL’s system. This inflates labor costs and increases errors that create further problems downstream.

- Reliance on paper-based picking processes. Manual processes slow distribution cycle time and reduce order accuracy, ultimately angering customers and impacting future sales.

The Solution: Use Technology to Enable Warehouse Process Automation

When it comes to automating processes within the distribution warehouse, you don’t need to build it; you can buy it. Look for 3PLs that have invested to become digital logistics leaders. Here are just some of the things they can bring to the table for warehouse process automation:

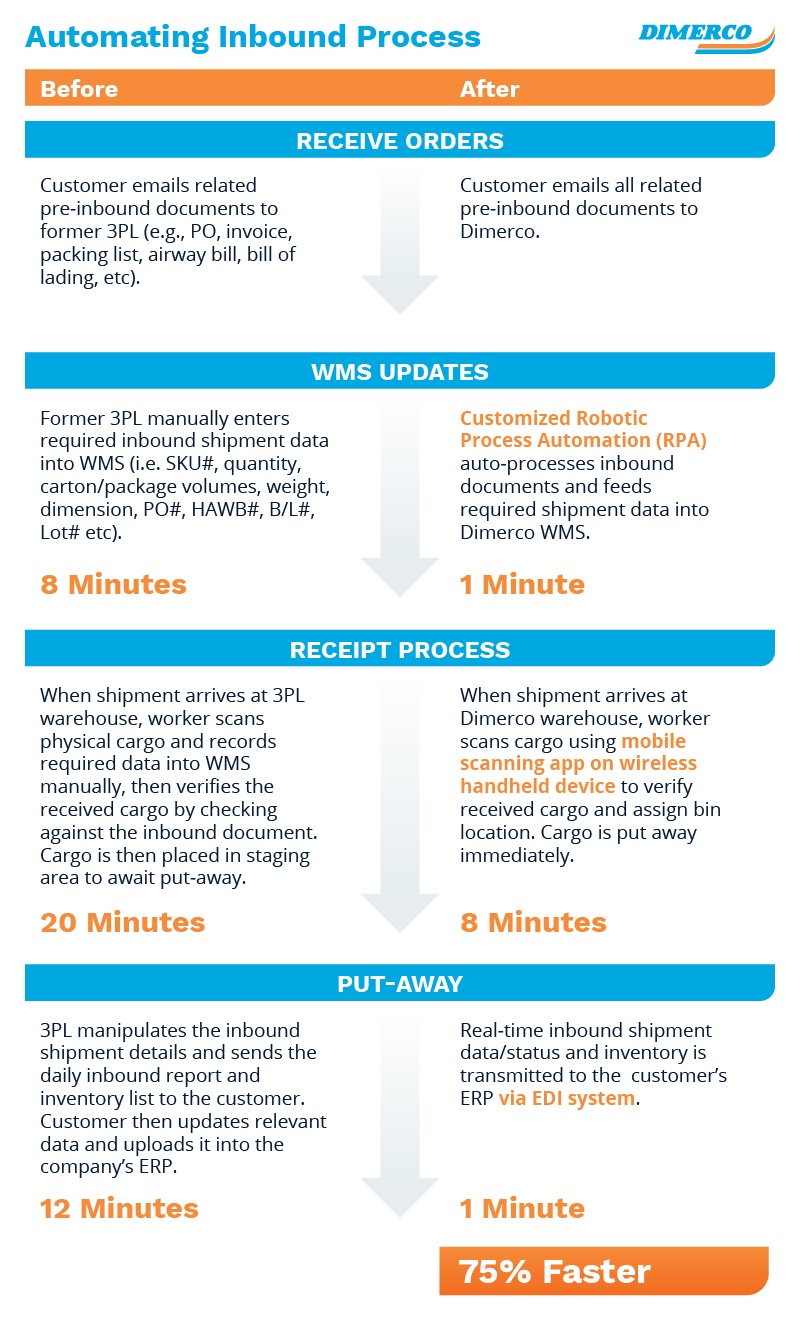

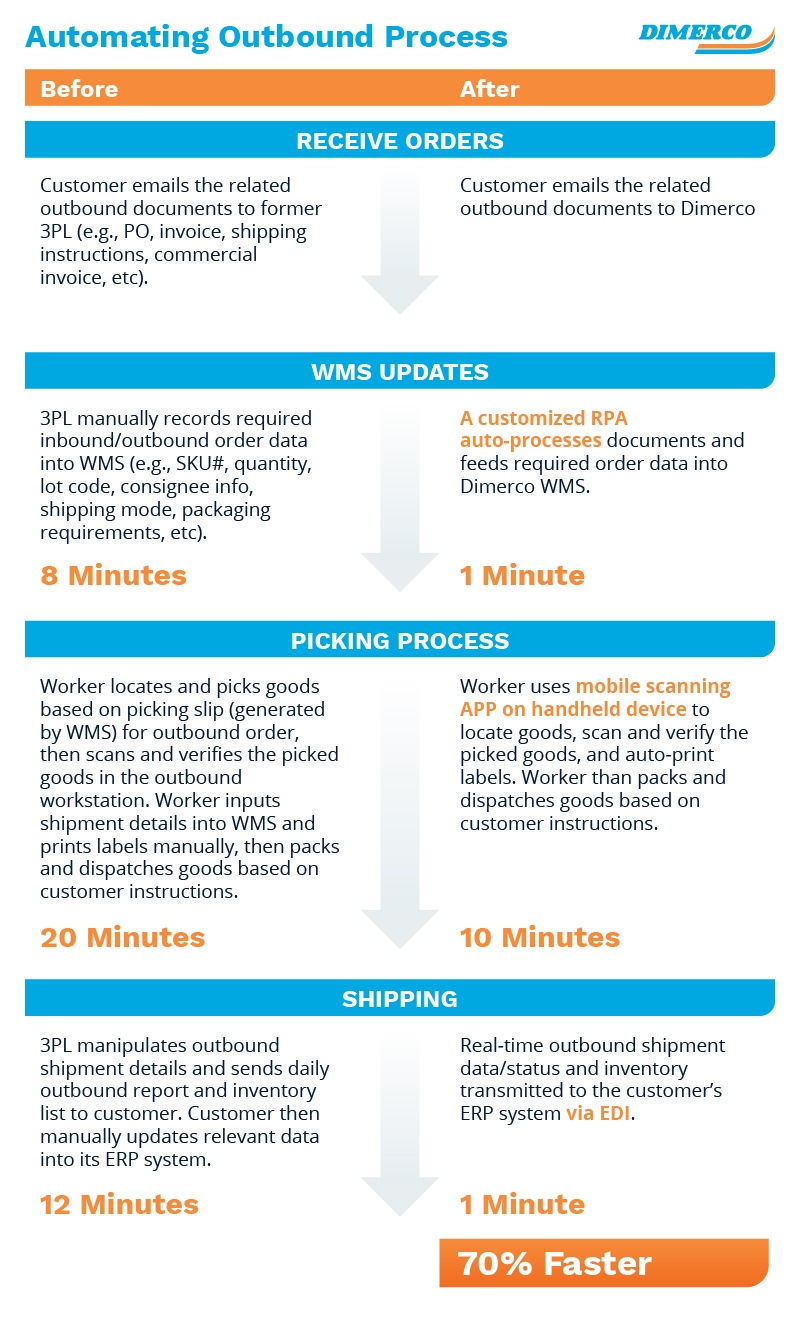

- Robotic Process Automation (RPA). RPA can be used to process documents provided by the customer. Using optical technology and simple programming logic, documents can be scanned and selected data automatically uploaded to relevant fields within the warehouse management system (WMS). This eliminates data entry and any potential for error, assuming the incoming customer data is correct.

- Mobile scanning APPs. Such APPs, installed on mobile, handheld devices, ensure accuracy for inbound and outbound distribution to the PO/item or carton level. Item scans verify that warehouse actions are in sync with customer instructions. Scans immediately upload to the WMS, giving you real-time data on order status.

- Advanced EDI. Processes that rely on emails and spreadsheets won’t provide an up-to-date view of your distribution operation. Look for 3PLs that can quickly establish a direct connection between your systems and their digital logistics platform.

- Visibility platforms to view in-process orders and inventory. Customers can monitor status anytime, anywhere, from any device using a secure login.

- Custom integration for visibility within your own system. Data-driven 3PLs have IT teams dedicated to customer integrations. They can program APIs to feed real-time status updates directly into the customer’s system. In this way, members of the customer’s team can view up-to-date status within their own system.

You can’t afford to invest the time and money required to build a global warehousing and distribution capability. The good news is you don’t have to if you align with the right 3PL.

The following charts illustrate how Dimerco applied many of these technologies to modernize and improve distribution from Hong Kong for a leading technology company. At each step – both inbound and outbound – the application of warehouse process automation reduces time and labor costs and increases accuracy by eliminating the potential for human error.

Businesses Must Automate Warehouses Processes to Stay Competitive

One of the worst enemies of change in the warehouse distribution industry is inertia – the way we’ve always done it. Spreadsheets and data-entry clerks are no longer just signs of old-school inefficiency. They are signs of a company that’s out of step with 21st century commerce.

If your warehouse distribution operations are still highly manual and paper-based, you should embrace digital transformation for this area just as your company has done already for its finance, marketing and HR management processes. That means partnering with 3PLs that are leading the way in warehouse process automation.

To discuss how Dimerco can take time and cost out of your product distribution processes, contact us today to start a discussion.