If you need to establish outbound distribution from Asia, the best location for an Asia warehouse will differ depending on your unique situation.

In our work with shippers, Dimerco has found the decision process comes down to six basic questions. Once answered, the decision on where to locate your warehouse in China or Southeast Asia becomes clearer. This article looks at each of these questions in turn.

For a more comprehensive guide on establishing an optimized distribution network in Asia, read our eBook: “Strategic Warehousing in Asia-Pac.”

1. What service levels do you require?

Millions of dollars of profit could be added or lost based on where you locate your Asia warehouse, so identifying the low-cost option seems logical. But if your cost-optimized network doesn’t get it to your customer when they want it, it won’t work.

Here’s an example. A major global distributor of semiconductor and other tech products ships most of its Asia-made products via air freight from Dimerco’s Singapore distribution center. Since Singapore is one of Asia’s top logistics hubs, you’ll pay a premium for warehouse space and labor there. But the products in question are high-demand items for which buyers require rapid order-to-delivery cycle times.

Here’s an example. A major global distributor of semiconductor and other tech products ships most of its Asia-made products via air freight from Dimerco’s Singapore distribution center. Since Singapore is one of Asia’s top logistics hubs, you’ll pay a premium for warehouse space and labor there. But the products in question are high-demand items for which buyers require rapid order-to-delivery cycle times.

Singapore was chosen because Singapore Changi Airport has more direct links to other global gateways than any other port in Asia.

2. What will taxes and duties cost?

If you manufacture products like semiconductor equipment and pharmaceuticals, warehousing and transportation costs may be a secondary consideration when assessing the best place for your Asia distribution center. The reason is the hefty cost of taxes and duties in some countries versus others. For instance, import value-added tax rates are 13% in China, 10% in Vietnam and Malaysia, and 0% in freeports like Hong Kong, according to Zonos. Millions of dollars hang in the balance. That’s why, at companies with high-value goods, the finance team is often a key participant in the warehouse search process.

Note that the wise use of free trade zones and bonded warehousing in Asia can defer and even avoid duty and tax payments. A bonded warehouse strategy could be a way to locate your goods in the lowest cost transportation hub, but still minimize what you owe the government to operate there.

3. Is it easy to do business in this country?

This could be a very important consideration, particularly if you need to move swiftly. Every country will involve an application process to operate a warehouse, and there could be further licensing requirements. In larger countries, like India, the process may involve adherence to national, regional and local regulations, adding time and complexity. In fact, one of Dimerco’s fastest growing services is advising companies how to enter the India market efficiently.

One way to avoid getting wrapped up in administrative red tape is to partner with a third-party logistics company (3PL) that already has a warehouse in your preferred market. In addition to having space available, they can help you navigate the bureaucracy based on a solid understanding of local laws and regulations.

The following chart from World Bank ranks countries on how easy it is to do business there.

4. Does the country have a well-developed transportation infrastructure?

Ideally, you want your distribution warehouse to be close to ports with adequate freight capacity to handle your shipment volumes. Not surprisingly, you’ll pay more for this advantage. A warehouse further from the port will be less expensive but if the road infrastructure in the country is not developed, the related slowdowns and frustrations may outweigh any cost advantages.

A resourceful freight forwarder can help overcome a country’s transportation infrastructure shortfalls. For instance, one large CPG customer of Dimerco manufacturers and warehouses products in Vietnam, where operating costs are relatively low and where freight capacity can be unreliable during busy shipping seasons. When FCL capacity from Vietnam to the USA became a problem, the company used Dimerco’s cross-border trucking solution in Southeast Asia to ship goods via bonded truck from Vietnam to Dimerco’s FTZ warehouse in Shenzhen, China. From there, the cargo was prepared and shipped via FCL to the USA from South China – a solution that turned out to be far more predictable and reliable for the customer.

Leveraging the expertise of Asia logistics services providers can help you assess and navigate the transportation infrastructure of different countries, ensuring optimal connectivity and efficiency for your distribution network

5. Is it a good labor market?

There are two aspects to assessing warehouse labor as a criterion for selecting an Asia warehouse location: availability and cost.

Unlike the US and Europe, warehouses in Asia are largely non-automated, so high-volume warehouse operations will require lots of bodies. You’ll want to make sure adequate labor is available, particularly during peak season – whether you run your own warehouse or contract with a 3PL.

When aiming for efficient warehouse operations in this context, it’s crucial to consider the labor market strategically while selecting the best Asia warehouse for efficiency. This ensures a workforce that is not only available but also capable of meeting demands seamlessly.

Labor rates will vary country to country (see accompanying chart), so you’ll want to do your research on labor costs. You’ll pay more for labor in advanced logistics markets like Hong Kong and Taiwan than you would in Malaysia or Vietnam, for instance. But the efficiency of transportation from these global transportation hubs may outweigh any labor cost considerations.

6. What are the combined costs for each warehouse location option?

The final question ideally involves a total landed cost comparison for each market under consideration. But, frankly, a purely numbers-based analysis can be hard when doing a hypothetical assessment.

For example, labor rates in one market may be half those of a neighboring market. But if work quality and productivity rates there are poor, is it really the better option?

Most companies we work with develop their own assessment model for determining the best location for an Asia warehouse. They assign different weighting factors to each criterion and then make a decision.

One global tech firm, a customer of Dimerco, recently completed a warehouse assessment project where they examined five potential markets against the major criteria covered in this article, plus more granular data, including:

- number of the local airport’s connections to global gateways

- number of flights in a day

- the airport’s total freight capacity

- average customer clearance time

In its analysis, this company prioritized air freight capacity and speed above all else.

Key Factors for an Asia Warehouse Location

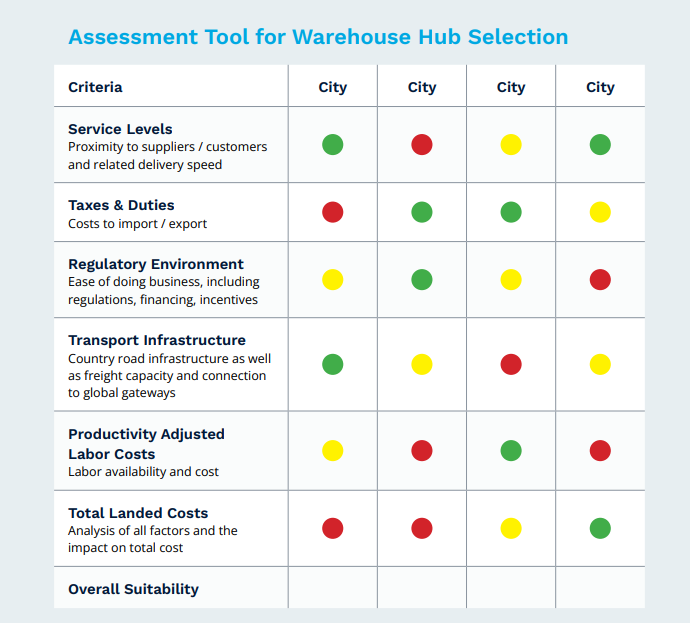

To select the optimal Asia warehouse location, carefully consider the factors outlined in the provided chart.

Service Levels are critical. Proximity to both suppliers and customers can significantly reduce transportation costs and lead times. A well-positioned warehouse can expedite order fulfillment and enhance customer satisfaction.

Taxes and Duties can significantly impact your bottom line. Minimizing costs by selecting a location with favorable tax and duty regimes is crucial. Additionally, considering locations within free trade zones can offer reduced or eliminated tariffs.

The Regulatory Environment can either facilitate or hinder your operations. A business-friendly environment can streamline operations and reduce compliance costs. Leveraging government incentives, such as tax breaks and subsidies, can further improve your bottom line.

A robust Transportation Infrastructure is essential for efficient logistics. A location with access to well-connected ports, efficient road and rail networks, and air freight connectivity can ensure timely deliveries.

Labor Costs and Productivity are important factors to consider. Balancing labor costs with productivity and skill levels is essential. Additionally, understanding local labor laws and regulations can help minimize operational risks.

Total Landed Cost is a comprehensive analysis of all costs associated with the warehouse location, including transportation, warehousing, labor, and taxes. Identifying the most cost-effective location is key to optimizing your supply chain.

By carefully considering these factors and conducting a thorough analysis, you can select the optimal location for your Asia warehouse that aligns with your business objectives and maximizes your supply chain efficiency.

Confer with 3PL partners early when assessing the best Asia warehouse location

If you’d like to dive deeper into this subject, make sure to read our eBook.

One mistake shippers make when analyzing their distribution center options in Asia is waiting to involve 3PL partners until after they’ve decided on their preferred market. A 3PL like Dimerco, with warehouse locations across China, Southeast Asia and India, will already have the answer to many of the questions you’ll need to research – about taxes, regulations, labor rates, space rates, etc. In fact, the right partner can cut your Asia warehouse selection process by 4–5 months.

Want to learn more? Contact a Dimerco Asia logistics services warehouse expert today to start a conversation.

.