Home »

8 Ways to Streamline Global Logistics for Electronics Products

What Makes Electronics Supply Chains Unique?

Every supply chain aims for the same goals — right product, right place, right time — but electronics logistics brings a unique level of urgency and complexity.

Fast product cycles, high-value components, and globalized production hubs — especially in Asia — make streamlining your global logistics essential for competitiveness. A delay of just one day can jeopardize production schedules and erode margins.

This guide outlines eight actionable strategies to make your electronics supply chain faster, leaner, and more resilient.

Download Guide

If you prefer to download this article as a PDF, just complete the form. Otherwise, keep reading.

Challenges Facing the Electronics Supply Chain

Short Product Lifecycles

Time-Critical Deliveries

When the lawn chairs arrive a few days late, there is frustration for sure, but the downside impact is limited. In contrast, inexact shipping schedules for electronics components could halt production lines, delay product launches and anger customers. You need reliable shipping partners that consistently hit delivery timelines and provide early visibility to delays to plan alternative strategies.

Asia Production Hubs

Most tech product supply chains are Asia-centric. China, Taiwan and India are key markets for manufacturing services. And electronics are an important export for China, South Korea, Taiwan, Malaysia, Singapore, Philippines, Thailand, Vietnam and Japan. You need freight forwarding partners that can commit the freight capacity you require to, from and within Asia-Pac.

Dynamic Market Conditions

Predictable is not a word used to describe tech product supply chains. Today, those supply chains are being impacted by a backlog of high-powered chips to support AI, trade tensions and tariffs, and factory relocations driven by a China Plus One strategy. Tomorrow, it will be these and another set of market realities. You need agile shipping and logistics partners that thrive in a dynamic business climate. In the freight services market, size has its virtues, but partners who are not flexible and nimble will simply slow you down.

1) Manage Expansion into New Markets with Expert Guidance

When moving into a new market, tech manufacturers lack the local market knowledge required to comply with regulatory and customs requirements and capitalize on economic development incentives.

Challenge

Trade tensions have led some manufacturers to shift production from China to other Asian countries. But many act before thoroughly researching challenges and opportunities.

- Underestimating local logistics requirements, like permits and licenses, can delay projects and hike costs

- Poor knowledge of how customs duties and taxes are assigned can result in overpayments

- Overlooking available economic development incentives may cause you to miss out on millions of dollars in tax abatements and other benefits

While there is significant trade and cooperation between Asian nations, each country has its own set of rules, regulations and economic development incentives. Small and medium-sized enterprises just don’t have the internal resources and expertise required to enter new markets quickly and successfully.

Solution

If you’re expanding from China into Southeast Asia or India, you don’t need to become the local logistics expert in these markets. A forwarding and logistics partner that has been operating in these markets for years can educate you on the ins and outs of doing business there.

Example: For the world’s largest power supply product manufacturer, Dimerco Express Group provided guidance on the customs duty and tax implications of establishing a new factory in Bangalore, India. Based on this advice, the company was able to cut 10% off an Extra Duty Deposit – a 6-figure net savings – and enjoy hassle-free movement of all machinery from China to India without a physical examination or customs queries.

Your freight forwarders and 3PLs may not be execution-only partners. Because of their local market expertise, they can often provide an important consulting role when managing complex relocations.

Relocation & Expansion: Case Example

Dimerco helps global tech-product manufacturer establish distribution operations in Singapore

A large, global manufacturer of computer memory products wanted to set up distribution operations in Singapore but was not a registered company there. Dimerco worked with the Inland Revenue Authority of Singapore to establish itself as the company’s agent. Today, Dimerco handles all import/ export shipping and management of the manufacturer’s distribution operation within the Airport Logistics Park in Singapore (located in a free trade zone within walking distance of the Dimerco’s air freight facility). Dimerco’s services allowed the manufacturer to:

2) Leverage Bonded Warehousing to Improve Cash Flow

Many electronics companies do not capitalize on the advantages of operating in a customs bonded warehouse or Free Trade Zone (FTZ), especially when importing goods from abroad. As a result, they pay duties and VAT before the goods are sold, which impacts cash flow.

Challenge

The primary value of a bonded warehouse is not hard to understand. It helps you defer (and sometimes avoid) duties, taxes or fees on imports or exports until they ship from the warehouse.

The complexity comes in the different ways various governments and customs agencies administer such programs. China, for instance, has several different types of bonded warehouses and zones, and it’s important to choose the right one based on your situation and needs. Most companies simply don’t have the resources to understand and fully capitalize on the different import/export strategies available.

Solution

Manufacturers can utilize bonded warehouses or Free Trade Zone (FTZ) warehouses to dramatically improve cash flow. Such facilities may allow you to:

Defer duty payments.

Decrease order-to-delivery times.

Avoid duties on re-exported products.

Reduce cost and complexity of export shipments.

Bonded Warehousing: Case Example

Using a Bonded Warehouse for eCommerce Order Fulfillment

Dimerco operates Indonesia’s first and only eCommerce Bonded Logistics Center (BLC). The 10,000+ square meter bonded warehouse provides an integrated, multimodal transport service for faster eCommerce fulfillment and reduced costs. The bonded warehouse allows foreign goods to enter Indonesia with no requirement to pay duty and tax in advance, providing a significant cash flow advantage to regional retailers. Since goods are already in the country under bonded storage, order-to-delivery lead times are much faster – about 1-3 days. Compared to B2C deliveries, lead time is shortened by more than 10 days.

3) Use Air Freight Consolidation to Reduce Cost Without Sacrificing Speed

Electronics manufacturers rush to ship goods as fast as possible and, as a result, inflate global shipping costs.

Challenge

Consolidation of air freight shipments is a tried-and-true strategy for reducing shipping costs. Nothing new here. But many technology manufacturers ignore consolidation opportunities. Why?

Solution

Consolidated air freight from several shippers moves under a single master Air Waybill under the forwarder’s name. The forwarder provides house Air Waybills to the individual shippers. The consolidated loads may be put into a single Unit Loading Device (ULD) or carried loose, depending on the product.

With the right shipping partner, you can have the best of both worlds: rapid shipments that meet delivery standards but at a lower consolidated rate. The key is finding forwarders that have committed capacity with frequent flights in your high-demand lanes.

Case Example: Fast and Cost-Efficient—You Can Have Both

A large, global semiconductor manufacturer manages inbound transportation for more than 20 of its component suppliers from Singapore to both Shanghai and Hong Kong. The goal: rapid, reliable shipments at the lowest possible cost. The company’s freight forwarder, Dimerco, consolidates air shipments to both destinations twice weekly.

Suppliers simply alert Dimerco when freight is ready and the forwarder picks up and stages goods for the next consolidated shipment. Goods that need to move more urgently are managed separately. But most shipments are consolidated. As a result, the customer has reduced its overall costs, and still enjoys a very predictable, reliable flow of inbound products.

4) Optimize Packaging and Shipment Prep for Protection and Efficiency

Electronics shippers add costs and shipping time through unsuitable packaging and shipment preparation

Challenge

Despite the fragile nature of many electronics products, manufacturers often pack products in inexpensive, poor-quality cartons that can’t withstand the rigors of an international freight journey through multiple touch points, warehouses and airports. During the rainy season, insufficient protection may result in cartons getting wet during transfer between the aircraft and the warehouse. When end-customers reject wet or damaged cartons, it erodes customer confidence and adds costs to reship products.

Solution

Damage during shipping isn’t always the fault of carriers and other shipping partners. If the problem is linked to the carton itself, work with your teammates upstream in the supply chain to source more durable packaging, such as 3-ply versus 2-ply cardboard material. Your forwarder can make recommendations, particularly if it has experience working with other tech manufacturers.

Forwarders can also provide enhanced packaging services by, for instance, placing edge protectors on corners and wrapping with multiple layers of shrink wrap to guard against rain or rough handling.

When preparing goods for shipment, manufacturers should ensure pallet heights do not exceed 155 cm so they can fit in the belly hold of a passenger aircraft. Otherwise, your shipping options will be limited to cargo planes. If passenger flights are also an option for your cargo shipments, you’ll have more and cheaper alternatives.

Lastly, don’t forget to mention in advance if your cargo is fragile and not stackable. Follow all regulatory packaging requirements, such as dangerous goods material packing, so your cargo can be clearly identified.

Palletization Best Practices

High-value electronics products deserve extra attention and investment during the palletization process. Follow these guidelines:

Prior to palletization

- Inspect cartons received to ensure they are free from dents, creases, scratches, wet damage, stains, missing labels or markings.

- Ensure pallet is designed to carry the weight of the goods.

- Use cartons that are strong enough for international transportation.

Pallet loading

- Each carton row should be the same height. You can either stack cartons vertically or interlock (stagger) them. An interlocking method is usually better to avoid volume movement as it can reduce up to 50% of the top-to-bottom compression resistance potential. NOTE: the best stacking method may depend on carton characteristics.

- Avoid cartons that overhang, as this is 40% weaker than ideal.

- Minimize gaps in stacking patterns to use the pallet’s cubic space efficiently.

- Follow all carton orientation symbols (e.g., this side up) and make sure all labels are readable.

- Distribute weight evenly to avoid excess pressure on box contents. Heavier cartons should be placed on the bottom layer.

- Shrink wrap the whole pallet, preferably after applying an angle bar.

- Make sure you are banding and cross-strapping the pallet in compliance with local regulations.

Transporting cartons

- Make sure you use the correct size of container for your goods.

- Secure cargo inside the container with bubble wrap or paper to avoid internal movement.

- Use stretch wrap to weatherproof cartons and secure the load. Invest in strong stretch wrap.

5) Get the Paperwork Right — Every Time

Electronics companies spend millions more per year to ship via air freight only to have shipments delayed due to clerical errors. To get it there on time, get the paperwork right.

Challenge

You can get yourself to the airport for an international flight, but if you forget your passport or it’s out of date, you’re not going anywhere. Same with global freight. Forwarders often receive the product but cannot tender the load because paperwork from the manufacturer is either missing or incorrect.

Export: Failure to submit complete and correct export data or supporting documents to customs houses or airline terminals may result in penalties and offloading your export shipment.

Import: Failure to submit complete and correct import data or supporting documents may delay customs clearance and will incur storage charges at destination.

Solution

Don’t allow simple clerical errors to delay shipments. Establish clear internal SOPs that ensure crucial documents are checked and double-checked for accuracy. The right freight forwarder partner may catch items that you miss, but ultimately you, the shipper, are responsible for complete and accurate paperwork.

Beware of freight forwarders who have yet to embrace digital processes. Manual data entry is the enemy when it comes to accurate shipping documents. You’ll gain a huge advantage by aligning with forwarders that run paperless operations and can eliminate spreadsheets, emails and data entry by automating data transfer.

Need some help developing your own SOPs? Check out the shipping document checklist that follows.

Document Checklist for Global Shipments

- Have you included item HS codes on the invoice and packing list?

- Have you input the declared value of the shipment in the correct currency?

- Is the piece count correct?

- If you’ve palletized, have you detailed the number of cartons on a pallet (e.g., 1PLT, 20 CTNs)?

- Does all the data match across all documents – invoice, packing list, shipper’s letter of instruction?

- Have you identified if freight is prepaid or collect and used the correct Incoterm?

- Have you instructed your forwarder who to contact at destination for swift handling?

- Is your cargo Dangerous Goods (DG) and have you provided a Safety Data Sheet (SDS)?

- Does your shipment require special import/export permits or licenses?

- Does your shipment require special handling, such as temperature control, dry ice or DG?

- Do you need your forwarder to clear customs at destination or do you have your own broker?

- Do you need to insure the freight?

6) Accelerate Customs Clearance in Asia

The supply chains of many tech product manufacturers run through Asia, where unfamiliarity with local customs clearance processes can jeopardize delivery commitments.

Challenge

Although many electronics companies pay hefty air freight rates to have products shipped into China and Southeast Asia, shipments can be delayed by customs processes upon arrival. Such delays negate the value of faster air freight service. Working with the wrong logistics partners may increase the likelihood that your shipments will be delayed or selected for customs inspections.

Solution

One simple solution to speed customs clearance is to work with logistics partners that have Authorized Economic Operator (AEO) status. AEO-member companies adhere to rigid operational practices developed by the World Customs Organization to secure global trade. Because customs authorities see AEO members as low-risk, they grant them a number of financial and operational benefits, such as reduced inspection rates, fewer physical inspections and priority dispatch.

AEO programs are developed at the country level, and over 100 countries worldwide have programs in place. Many multi-nationals will only do business with AEO partners.

Because of the volume of goods electronics companies move into and out of China and Southeast Asia, it’s wise to work with forwarding partners that have invested to attain the highest possible AEO status in these countries. China Customs, for instance, has a 4-tier Enterprise Classification system, with the top-tier companies known as Advanced Certified Enterprises (ACE). ACE-certified companies like Dimerco can declare goods prior to arrival at China Customs and can cut clearance time as much as one full workday compared to non- AEO logistics providers.

Benefits of AEO Accreditation in China

Priority Treatment

Bonded transshipments – handling shortened 1-2 hours

Prior declaration and clearance – physical cargo release shortened 3-4 hours

Examinations with the lowest rate*

Special Privileges

Dedicated coordinator

After-hours access to customs applications

Deferred duty payment*

Exemption of guarantee*

AEO MRA (Mutual Recognition Arrangement) benefits

7) Automate Warehouse Operations to Eliminate Costly Errors

For high-volume, high-speed supply chains, delays and mistakes can’t always be tracked to the carrier or Customs. Manual warehouse processes can increase shipping mistakes as much as 15% and cause your labor rates to skyrocket.

Challenge

If you’re an electronics distributor, you regularly ship thousands of boxes to many different customers simultaneously. Each carton has a customer-specific label, but here’s the problem: your freight forwarder’s sorting facility may lack the systems to scan and efficiently route the proper cartons to the right customers.

Forwarders that sort boxes by literally eyeing very similar-looking bar code labels will ship 10–15% of those shipments to the wrong place—possibly to your competitors.

Incorrectly sorted and cross-labeled packages will impact the destination import clearance process, resulting in potential charges, discarding of high-value cargo, and reshipping costs.

If those same forwarders want to eliminate human error without investing to automate, the only way to do that is with – you guessed it – more humans to check and double-check outbound shipments. Who’s paying for this costly method of quality assurance? You are.

Solution

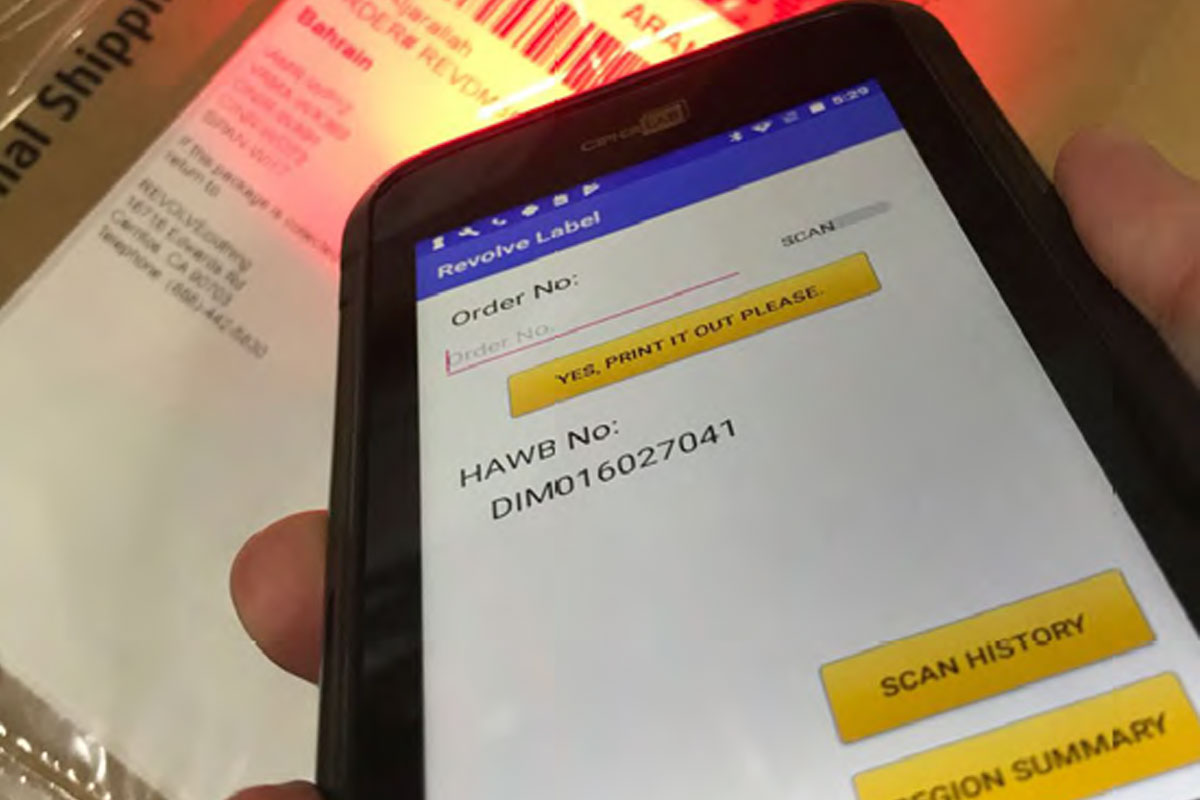

The solution is to use a forwarder with a digitized process for receiving and processing mixed customer freight. By receiving an Advanced Shipping Notice (ASN) with all shipping information before the cartons arrive, the forwarder can then scan barcode labels upon arrival to link the carton to a specific PO number and destination. The result: cartons move to multiple destinations quickly and accurately.

Shipping speed and freight rates are not the only criteria you should examine when choosing freight forwarding partners. When your distribution solution involves having your freight forwarder sort and segregate freight at a warehouse or container freight station, you must understand that, for many, this is not their core competency. Manual processes can put you behind schedule before your goods ever leave the warehouse.

Automating Warehouse Operations: Case Example

A large, global distributor of semiconductor products implemented its own Transportation Management System (TMS) in order to automate and integrate with suppliers and 3PLs. In support of this customer, Dimerco Express Group designed the best way to integrate all parties for improved customer satisfaction and service quality.

The company ships goods from multiple manufacturers so it’s imperative to prevent shipment of the wrong manufacturer’s products to the end customer. Dimerco’s IT solution involved:

The integration process involves receiving an ASN from the manufacturer and customs-related data from the broker. The smart device scanning and printing solution enables users to scan and verify each carton box, thereby preventing cross-shipment errors. Automating this quality-check process reduced errors as well as time – the process went from 1.5 minutes per carton to just a few seconds. Each scan is immediately recorded in the system, giving the distributor real-time visibility through the last mile.

Having PO details stored in the Purchase Order Management System allows Dimerco destination stations to reuse the data to ease the customs declaration process. This step eliminates any potential data entry errors and shortens pickup-to-delivery cycle time by at least a day.

8) Explore Cross-Border Trucking for Intra-Asia Shipments

Tech product manufacturers focused on supply chain speed often default to air freight for most international shipments. But ground freight can provide a fast, reliable, and much cheaper option across China and Southeast Asia countries.

Challenge

Intra-Asia trade has grown rapidly in recent years, and electronics companies are challenged to move goods fast and efficiently to and from the region’s top manufacturing and distribution hubs. But a failure to consider road freight as an option means companies are losing time (with ocean freight) or losing money (with air freight).

Solution

Electronics companies would be wise to take a closer look at cross-border trucking solutions for intra-Asia freight. Advantages include:

- Favorable cost to speed trade-off. You’ll add 3–4 days of transit time but can save close to 30% by shipping goods via truck vs. air.

- Flexibility. The more shipping options you have, particularly when freight capacity is tight, the more likely you are to secure needed freight capacity at a lower rate.

- Reliability. 3PLs now offer very predictable schedules for city-to-city moves between China and Southeast Asia, and within Southeast Asia.

- Real-time location tracking. This capability will vary with carriers, but top logistics companies exclusively use carrier partners with GPS technology so you can know exactly where your freight is and when it will arrive.

Adoption of cross-border road freight in Asia has gained popularity after a COVID-induced slowdown a few years back. High-value cargo like electronics will require armed security and escorts in some countries, reducing the savings potential vs. air. But those savings are still significant, as the chart on the next page shows. If you haven’t yet considered road freight shipping options between China and Southeast Asia countries, it’s an opportunity worth exploring.

Intra-Asia Shipping

Increased Time and Cost Savings by Changing from Air to an Alternate Mode

From |

To |

Transit Time & Price |

Air |

Ocean |

Trucking |

| Singapore | Shanghai | Ship time (days) | 3 | 22 | 8 |

| Price | Highest | <32% | <44% | ||

| Ho Chi Minh City | Shanghai | Ship time (days) | 3 | 13 | 5 |

| Price | Highest | <14% | <18% | ||

| Penang | Shanghai | Ship time (days) | 3 | 25 | 7 |

| Price | Highest | <18% | <28% | ||

| Bangkok | Shanghai | Ship time (days) | 3 | 19 | 6 |

| Price | Highest | <17% | <15% |

Superior supply chains are built upon day-to-day logistics excellence

Unprecedented product demand, freight capacity challenges, trade tensions, aggressive competitors… Competing and winning in the global electronics marketplace has never been more difficult – or more essential.

In the end, the winners will be companies that manage their supply chains just a little bit better. That small difference creates happier customers, a faster cash cycle and higher product margins – the things that ultimately determine a business’s success or failure.

Transformative supply chain strategies that allow you to dominate competitors are possible, but rare. It’s the everyday execution that makes the difference. The tips in this eBook reflect hard-won distribution insights that Dimerco has gained over the years, managing millions of shipments for high-tech industry customers.

While not transformative individually, these tips suggest ways to fix issues common to many electronics supply chains, and then continuously improve day-to-day shipping practices.

When you do that – over time, with relentless precision – you can gain a competitive advantage.

That truly is transformative.

Dimerco connects Asia with the world like no other global 3PL.

Success in the electronics industry doesn’t hinge on sweeping changes — it’s built on consistent execution. Streamlining global logistics means staying ahead of delays, cutting unnecessary costs, and gaining end-to-end visibility across your electronics supply chain. Small improvements, done well and done often, make a big difference.

We integrate air and ocean freight, trade compliance and contract logistics services to make global supply chains more effective and efficient. The majority of our global shipping projects connect Asia’s logistics and manufacturing hubs with each other and with North America and Europe. We serve customers from 160+ Dimerco offices, 80+ contract logistics operations, and 200+ strategic partner agents throughout China, India, Asia Pacific, North America, and Europe. Contact us to start streamlining your global logistics today.